Advantages of our commercial fruit and vegetable slicing equipment:

- Reliability and efficiency

- Ideal addition to peeling machines

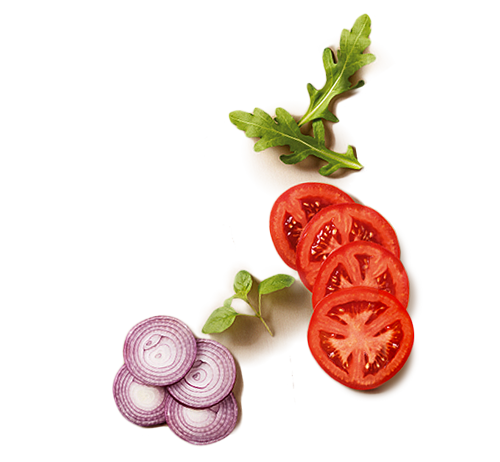

- Can also be used for raw, unpeeled product.

- Hygienic design: quick, safe and easy to clean

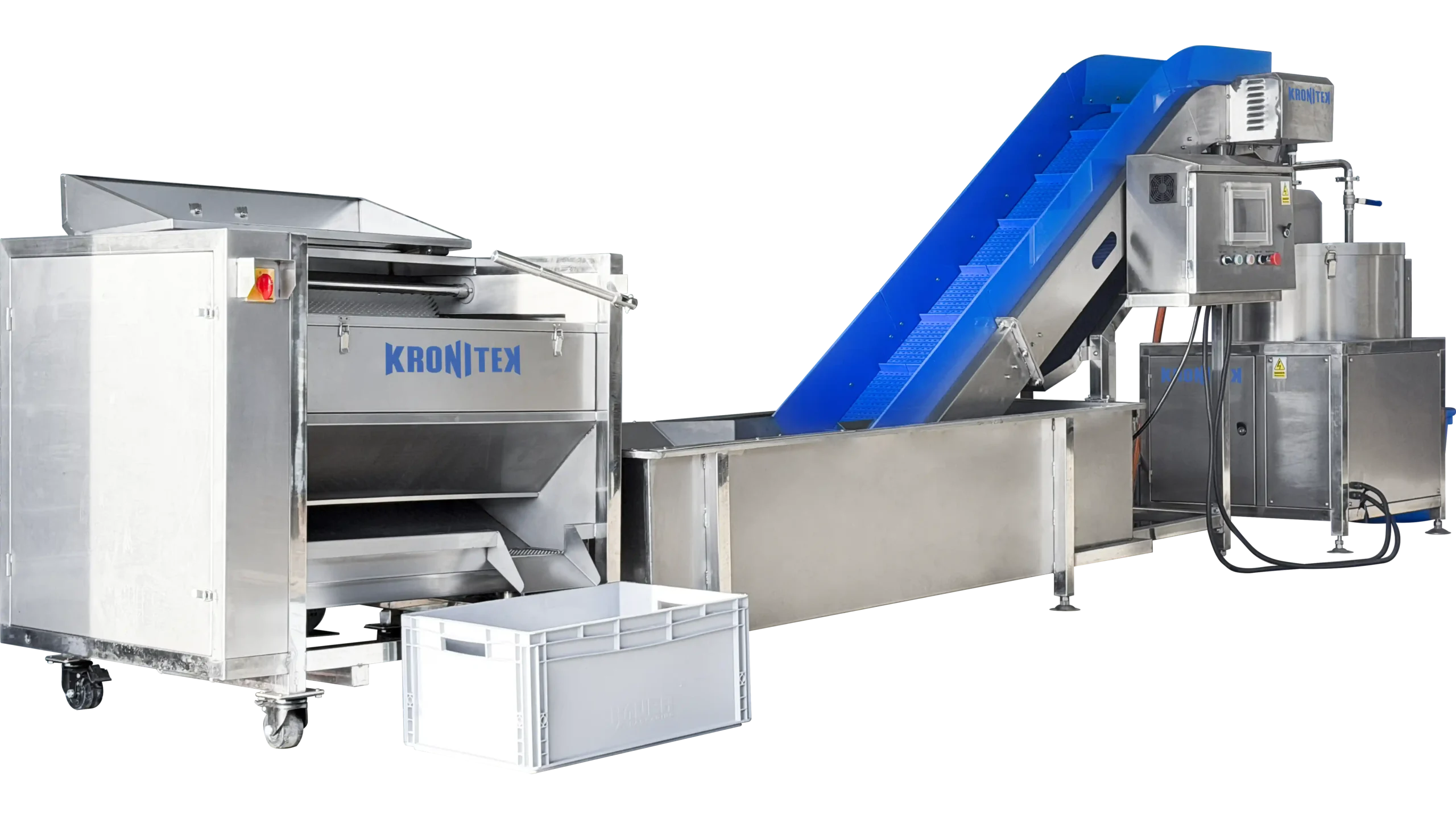

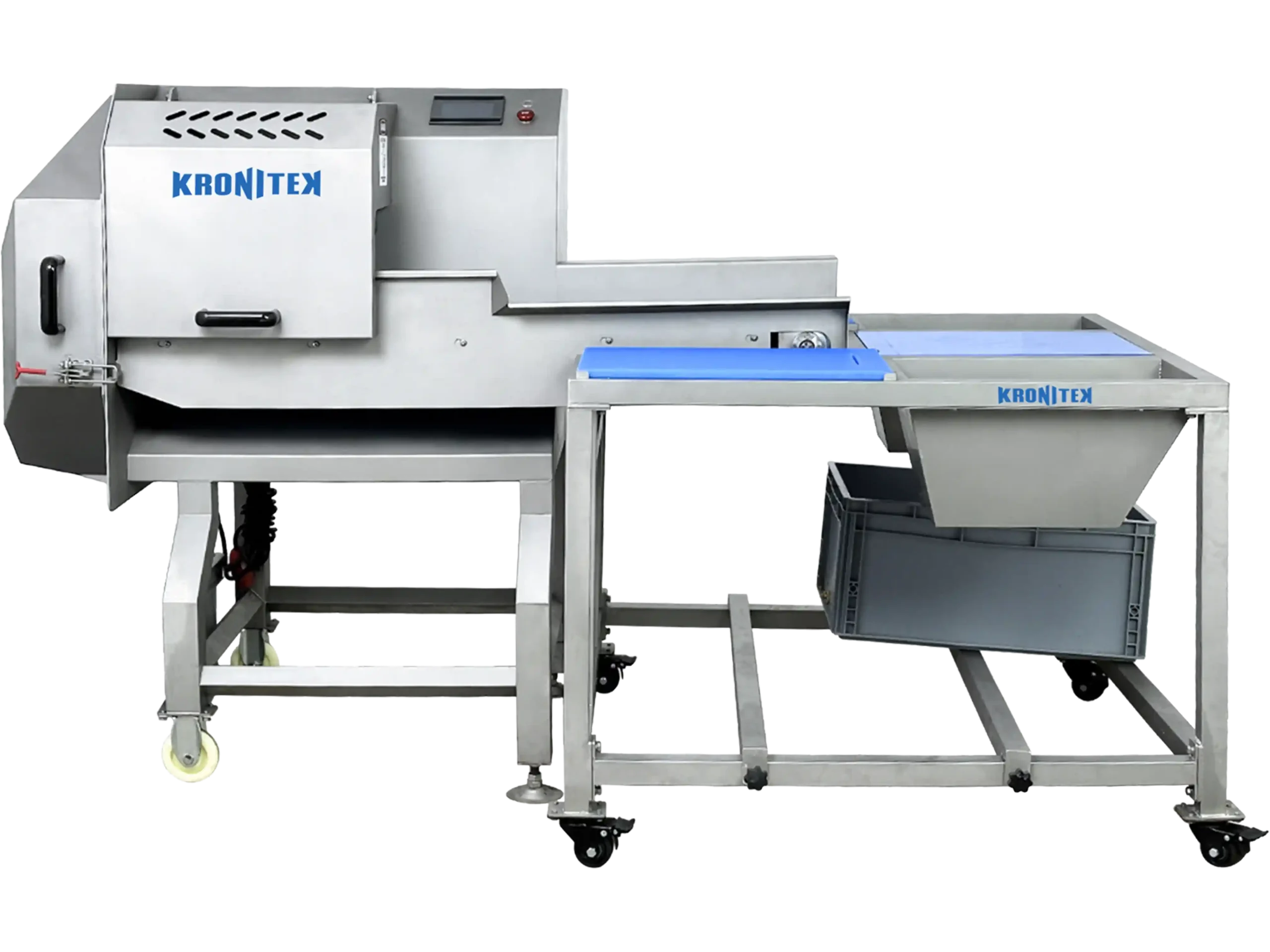

Separation of industrial machines

All heavy duty chopping machines of fruit and vegetable products are divided into:

- mechanical;

- manual.

Catering establishments are often equipped with units of mechanical type. Manual ones are used very rarely. These types of shredders are suitable for small outlets with fast food.

Vegetable shredders are classified depending on the use of the mechanism with which the cutting is carried out. As a chopping device can be installed:

Inside the disc vegetable slicer, fruits are pressed to the rotating disc mechanism – according to this principle, their shredding is carried out. Adjustable slicing parameters change the distance between the knife mechanism and the disc mechanism. Thus, it is possible to obtain slices of vegetables of different sizes in mm. The shape of the finished slices will be influenced by the design of the selected knife.

Depending on the size, all manufactured vegetable slicers are divided into four types:

- Large-sized – are characterized by a high rate of productivity, which can range from three hundred to nine hundred units of products per hour. They have two rotating speeds. They can handle raw or cooked vegetables. Loading can be done through two compartments, a larger and a smaller one. The hopper can be removed for cleaning. Suitable for large foodservice kitchens.

- Medium-sized – units with a capacity of eighty to more than two hundred kilograms of food units per hour. The knives rotate at low speed. Two types of cutting raw or cooked vegetables;

- Miniature – with a capacity of up to sixty kilograms per hour. Processes only vegetable or cheese products. They are purchased for the catering establishments, the daily attendance of which does not exceed eighty visitors.